Are you tired of traditional machining methods that are time-consuming and inefficient? Look no further than the gantry machining center, a cutting-edge technology that is transforming the world of industrial manufacturing. With its precision and versatility, this advanced machine has become an indispensable tool for businesses seeking to enhance their productivity and quality.

The Power of Gantry Machining Center

The gantry machining center is a highly sophisticated piece of equipment designed to handle complex machining tasks with utmost accuracy. Its unique gantry structure provides exceptional stability, allowing for precise movements in multiple axes simultaneously. This enables manufacturers to achieve intricate designs and tight tolerances that were once considered unattainable.

In addition to its precision, the gantry machining center offers remarkable flexibility. It can accommodate various materials such as metals, plastics, and composites, making it suitable for a wide range of industries including aerospace, automotive, and electronics. Whether you need to mill, drill or cut intricate shapes or patterns on large workpieces or small components – this machine can do it all!

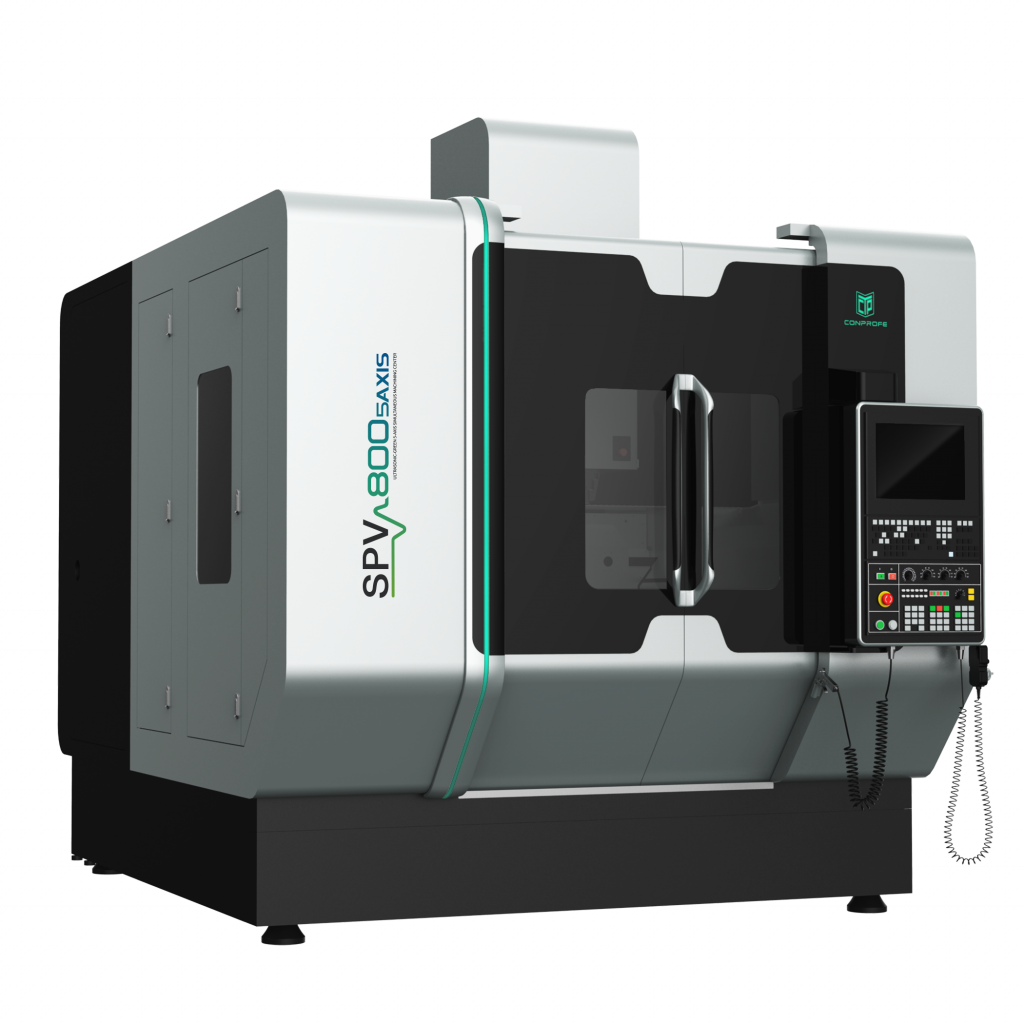

Conprofe Ultrasonic: A Game-Changing Innovation

When it comes to ensuring consistency in B2B quality control processes, Conprofe Ultrasonic has emerged as a game-changer in the industry. By harnessing ultrasonic technology combined with advanced software algorithms, Conprofe Ultrasonic offers real-time monitoring capabilities that enable businesses to detect even the slightest defects during production.

This innovative solution not only enhances product quality but also reduces waste by identifying potential issues early on in the manufacturing process. With Conprofe Ultrasonic’s comprehensive data analysis features and automated reporting system, businesses can make informed decisions regarding process optimization while maintaining consistent quality standards throughout their operations.

The Versatility of 5 Axis Vertical Machining Center

For manufacturers seeking unparalleled precision and efficiency, the 5 axis vertical machining center is a game-changer. This cutting-edge machine allows for simultaneous movement in five axes, enabling complex and intricate machining operations with exceptional accuracy.

The 5 axis vertical machining center offers unmatched versatility by allowing manufacturers to produce highly complex parts in a single setup. With its ability to rotate workpieces and access hard-to-reach areas, this machine eliminates the need for multiple setups or additional equipment, resulting in significant time and cost savings.

In Conclusion

The gantry machining center has revolutionized industrial manufacturing by providing unprecedented precision, flexibility, and efficiency. Combined with innovations like Conprofe Ultrasonic for quality control processes and the versatility of the 5 axis vertical machining center, businesses can achieve consistent high-quality products while maximizing productivity.

Embracing these advanced technologies not only ensures customer satisfaction but also positions companies at the forefront of their industries. So why settle for outdated methods when you can harness the power of gantry machining centers and other cutting-edge solutions to take your business to new heights?